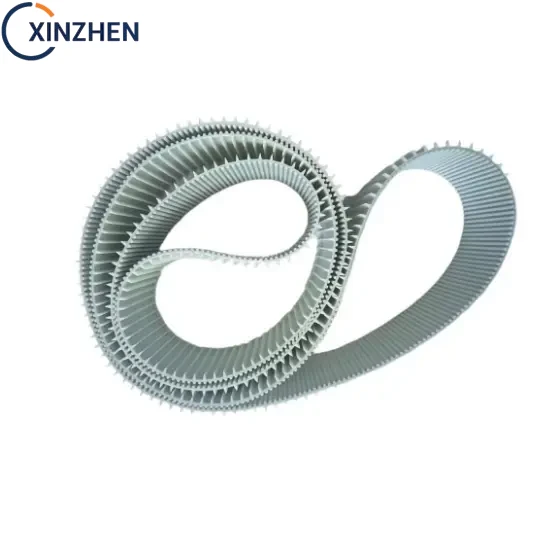

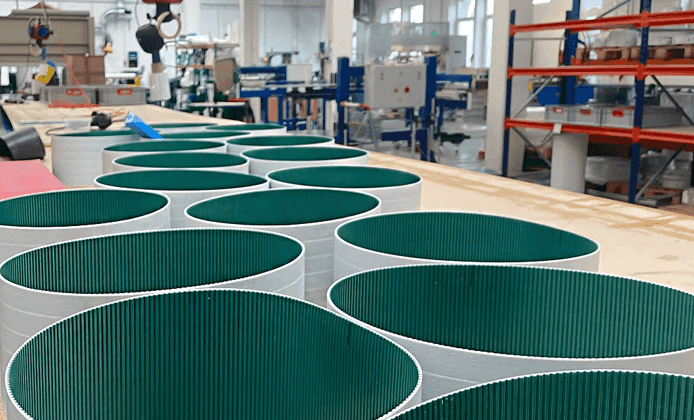

HTD5M+ Belt with Unique Block Design

Factory Direct Sales | Quality Assurance | Durable

| Order number | White Timing Belt | Circumference | 3000 (mm) |

| Brand | Xinzhen | Number of teeth | 600 |

| Item number | HTD5M+ Stopper | Custom processing | Yes |

| Model | HTD5M | Belt width | 50 (mm) |

| Drive belt type | Timing belt | Has a licensed private brand | Yes |

| Material | PU |

Multiple Uses and Wide Application

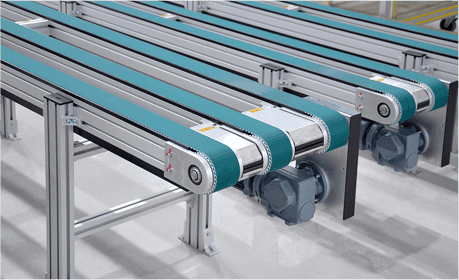

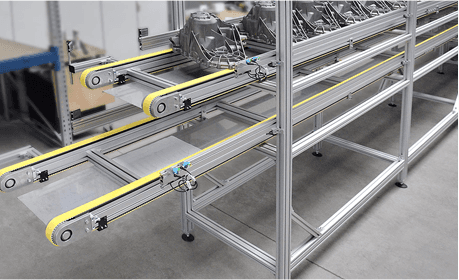

Widely used in glass, ceramics, aluminum, textiles, automation, woodworking machinery and other equipment fields, etc.

Glass Equipment Industry

Aluminum Profile Industry

Ceramic Industry

Textile Industry

Why Choose Us

Factory direct sales, quality assurance, durable, custom made

No Breakage

Abrasion Resistance

No Debonding

No Delamination

Waterproof and Oilproof

Customizable

A company with domestic and international competitiveness

Equipped with multiple sets of imported and domestic belt processing equipment

We can customize various types of belts according to customer requirements: PU timing belts, open timing belts, etc.

Customization Process

01

Customers provide drawings for proofing

02

The whole process takes 2-3 days

03

Confirm that the samples are correct and then go into mass production

04

High standards and strict attention to product details

05

Check the quantity and pack and ship

Foshan Xinzhen Industrial Belt Co., Ltd.

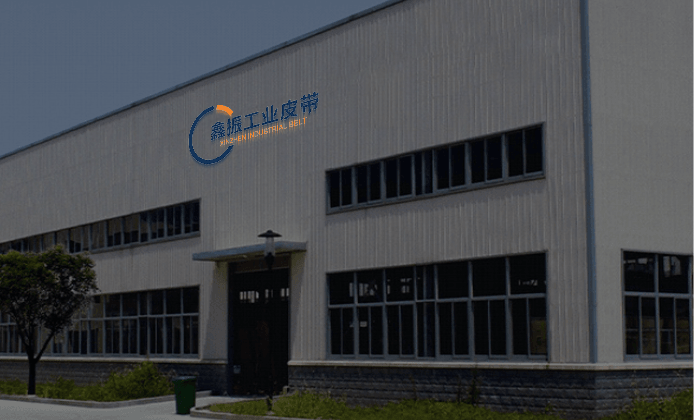

Foshan Xinzhen Industrial Belt Co., Ltd. is a manufacturer specializing in the production of polyurethane timing belts. It is located in Chancheng District, Foshan City, one of China's top 100 comprehensive strength areas. The company has complete production facilities and strong product development and testing technology. A full set of fully automated production lines with Italian timing belt technical parameters are introduced to specialize in the development, production, and operation of various polyurethane timing belts.

To meet the requirements of our customers, our company can professionally process special timing belts tailored to their specific needs. And is committed to building its brand. Quality is the life of an enterprise. The company has always adhered to the principle of "quality first, customer first". Strengthen the quality of employees, strive to improve product quality, and strictly implement product quality testing procedures.

Need help? Check our FAqs

Of course! You only need to provide the required size, material, structure, tooth shape, etc.

Our process begins with designing and developing the product in strict accordance with your specifications. Once the prototypes are ready, we conduct rigorous testing to ensure they meet all quality standards. Upon successful completion of testing, we proceed to mass production with the same attention to detail. To ensure complete customer satisfaction, we offer comprehensive after-sales support including professional installation guidance, detailed usage training, and prompt troubleshooting assistance throughout the product lifecycle.

Usually 1-3 years.

Standard models are typically shipped within 1–3 business days. For customized regular products, the standard lead time is approximately 7 business days. If you require special customizations, production and delivery typically take 2–4 weeks; however, highly complex orders may require additional time.

The lifespan of timing belts depends on several key factors. High-quality materials enhance durability and resistance to wear, while harsh operating conditions such as extreme temperatures, humidity, dust, or corrosive substances can accelerate deterioration. Excessive load and high-speed operation increase stress and wear on the belt. Proper maintenance, including regular tension checks, alignment adjustments, and contamination removal, significantly extends service life. To ensure optimal performance, it is recommended to inspect timing belts periodically and replace them when necessary based on actual operating conditions.